We are pleased to introduce the new Kroma LTD - mechanical seal range - fully split mechanical seals for pumps and mixers.

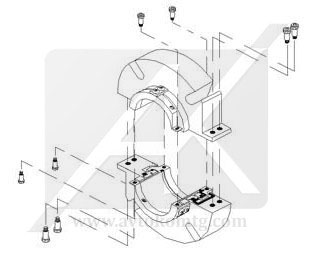

Split mechanical seals SPLITBOX for pumps and SPLITMIX for mixers allow quick and easy installation of the seal on the shaft without completely disassembling the equipment, which significantly reduces downtime.

The use of detachable mechanical seals significantly reduces the level of leakage, compared with the stuffing box in the absence of wear of the shaft sleeve.

Seals are easy to install without adhesive!

Detachable mechanical seals are used where the complete disassembly of equipment is very long and time-consuming and it is important to minimize production downtime:- pulp and paper industry;

- water treatment and sanitation;

- shipbuilding;

- heat power engineering;

- mine production.

Description of pluggable mechanical seals SPLITBOX.

Descriptions:

- consists of two assembled parts;

- does not require disassembling equipment;

- hydraulically unloaded;

- fixed spring unit;

- does not require adhesive joints for assembly;

- does not depend on the direction of rotation;

- quick and easy installation;

- low leakage rate;

- leak control;

- does not damage the shaft.

Work parameters:

- shaft diameters from 50 to 180mm (from 2 "to 7");

- pressure up to 10 bar;

- temperature -40/+150°C;

- rotation speed up to 10 m/s.

Materials:

Materials of friction pair rings:

- carbon graphite (A);

- silicon carbide (Q6).

Secondary seals:

- EPDM (E);

- FKM (V);

- NBR (P).

Springs:

- CrNiMo steel (G);

- other metal parts (G).

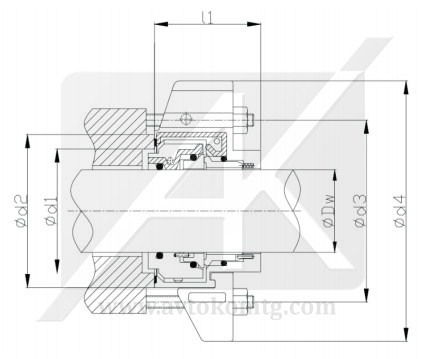

| Dw | d1 | d2 | d3min | d4 | l1 |

| 50 | 75 | 84 | 98 | 138 | 63 |

| 60 | 89 | 101 | 115 | 149 | 64 |

| 70 | 98 | 113 | 128 | 176 | 64 |

| 80 | 110 | 132 | 145 | 191 | 65 |

| 90 | 121 | 140 | 165 | 203 | 72,5 |

| 100 | 131 | 150 | 165 | 216 | 72,5 |

| 110 | 142 | 165 | 190 | 230 | 72,5 |

| 120 | 152 | 175 | 198 | 240 | 89,5 |

| 140 | 175 | 200 | 215 | 303 | 89,5 |

| 150 | 188 | 215 | 230 | 308 | 89,5 |

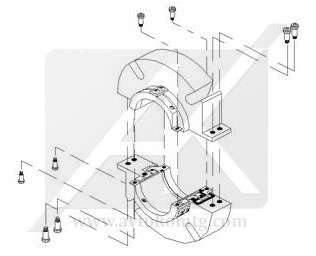

Description of pluggable mechanical seals SPLITMIX for mixers.

Analog:

Burgmann Splitex, AESSEAL RDS

Descriptions:

- completely detachable seal for mixers, reactors and other equipment;

- does not require complete disassembly of equipment - replacement and start-up with minimal downtime;

- quick and easy installation;

- suitable for most mixers;

- hydraulically unloaded;

- independent of shaft rotation direction.

Work parameters:

- shaft diameters from 50 to 180mm (from 2 "to 7");

- pressure up to 10 bar;

- temperature -40/+150°C;

- rotation speed up to 10 m/s.

Materials:

Materials of friction pair rings:

- carbon graphite (A);

- silicon carbide (Q6).

Secondary seals:

- EPDM (E);

- FKM (V);

- NBR (P).

Springs:

- CrNiMo steel (G);

- other metal parts (G).

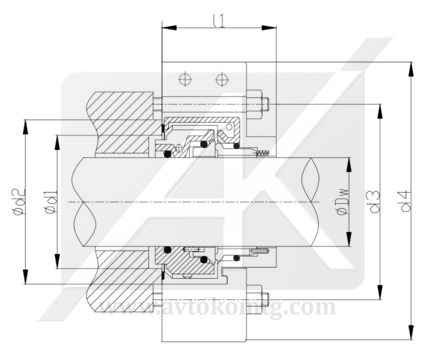

| Dw | d1 | d2 | d3min | d4 | l1 |

| 50 | 75 | 84 | 98 | 138 | 63 |

| 60 | 89 | 101 | 115 | 149 | 64 |

| 70 | 98 | 113 | 128 | 176 | 64 |

| 80 | 110 | 132 | 145 | 191 | 65 |

| 90 | 121 | 140 | 165 | 203 | 72,5 |

| 100 | 131 | 150 | 165 | 216 | 72,5 |

| 110 | 142 | 165 | 190 | 230 | 72,5 |

| 120 | 152 | 175 | 198 | 240 | 89,5 |

| 140 | 175 | 200 | 215 | 303 | 89,5 |

| 150 | 188 | 215 | 230 | 308 | 89,5 |

en

en

Русский [ru]

Русский [ru]