The AvtokomTehnolodgy group of companies has developed a recipe and mastered the production of rubber for the manufacture of sealing elements for packer equipment.

Downhole seals (packers) are used to isolate parts of the wellbore vertically and seal disturbed areas of the casing, as well as to disconnect the annular space zones located above and below the packers. Packers are used in the casing of oil, gas and injection wells during their operation and repair.

The rubber line developed by our specialists can be used as import substitution of expensive foreign materials. We produce rubber of different hardness, the physical and mechanical indicators of which are not inferior in their properties to products imported from the world's leading firms. We propose to manufacture the following items from these rubbers: o-rings, seals, packer-anchor equipment cuffs operating at a pressure drop at wellheads and temperatures over 150°C.

Rubber for sealing elements packer equipment.

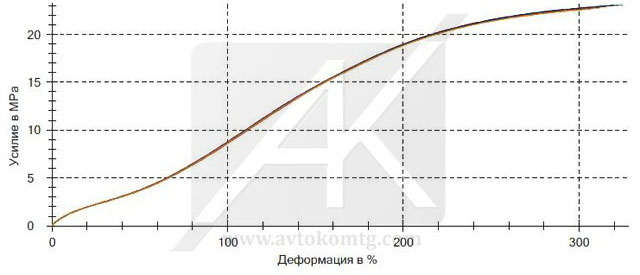

The main characteristics of rubber SH-7-62 for soft sealing elements.

Conditional strength at stretching, MPa |

23 |

Conditional stress at 100% elongation, MPa |

11,5 |

Relative elongation at break, % |

315 |

Residual elongation, % |

0 |

Hardness, conventional units Shor A |

80 |

Upper temperature limit of operation, °С |

150 |

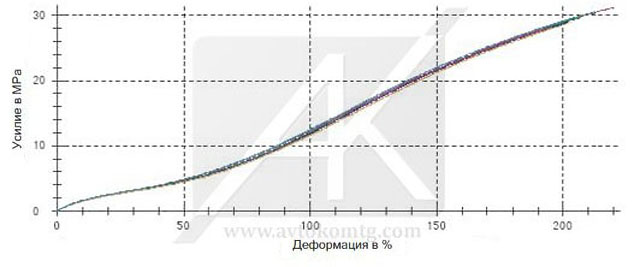

The main characteristics of rubber TH-5288 for solid sealing elements.

Conditional strength at stretching, MPa |

29 |

Conditional stress at 100% elongation, MPa |

19 |

Relative elongation at break, % |

200 |

Residual elongation, % |

0 |

Hardness, conventional units Shor A |

86 |

Upper temperature limit of operation, °С |

150 |

Rubber based on nitrile butadiene rubber.

Conditional tensile strength, MPa |

18,6 |

Relative elongation at break, % |

382 |

Hardness, conventional units Shor A |

76 |

Change of hardness after thermal-oxidative aging at 150°С*72h |

94 |

Module at 100% elongation, MPa |

6,2 |

| Module at 300% elongation, MPa | 3,2 |

T DSC, °С |

-47,7 |

T DMA, °С |

-46,9 |

Т hr, °С |

-60 |

Volume change in hydraulic oil T 46, 7 days |

0,62 % |

Volume change in hydraulic oil T 46, 26 days |

0,96 % |

Diesel swell, by mass, 24 h |

13 % |

Diesel swell, by mass, 48 h |

17 % |

Diesel swell, by mass, 72 h |

21 % |

Diesel swell, by mass, 96 h |

24 % |

Efficiency in the upper temperature range, °С |

120 |

Currently being developed and tested rubber:

- increased hardness (90-95 shore A);

- increased wear resistance;

- high heat resistance 160°С (short-term 170°С);

- with high physico-mechanical characteristics, low ODS (rubber from 40 MPa strength in difficult operating conditions).

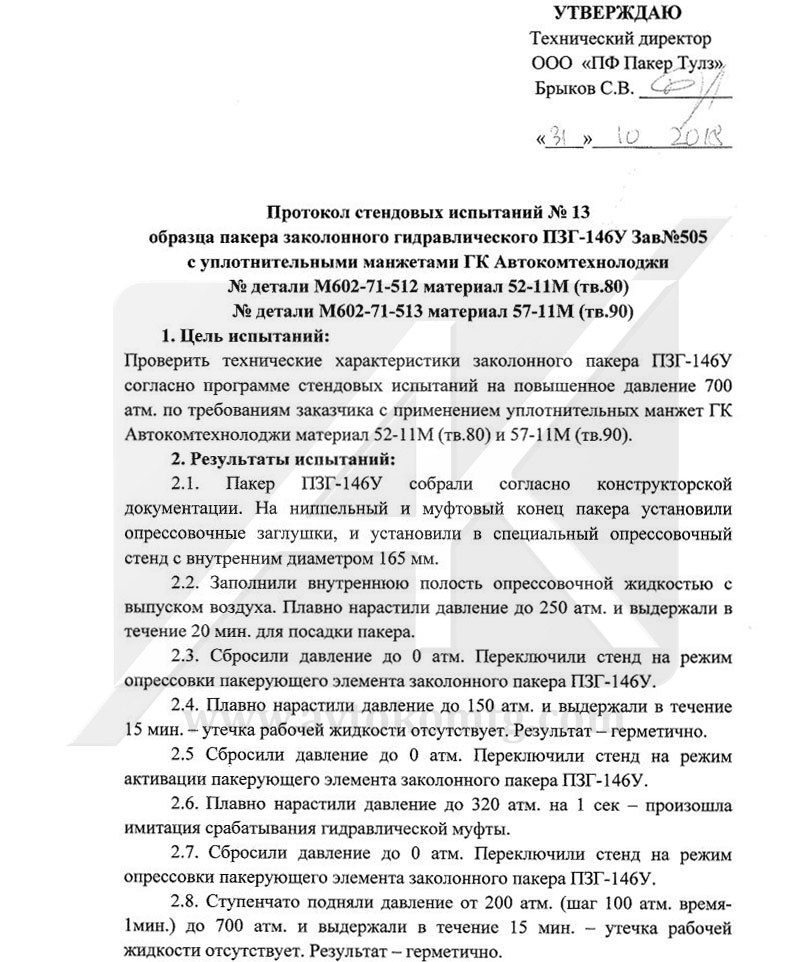

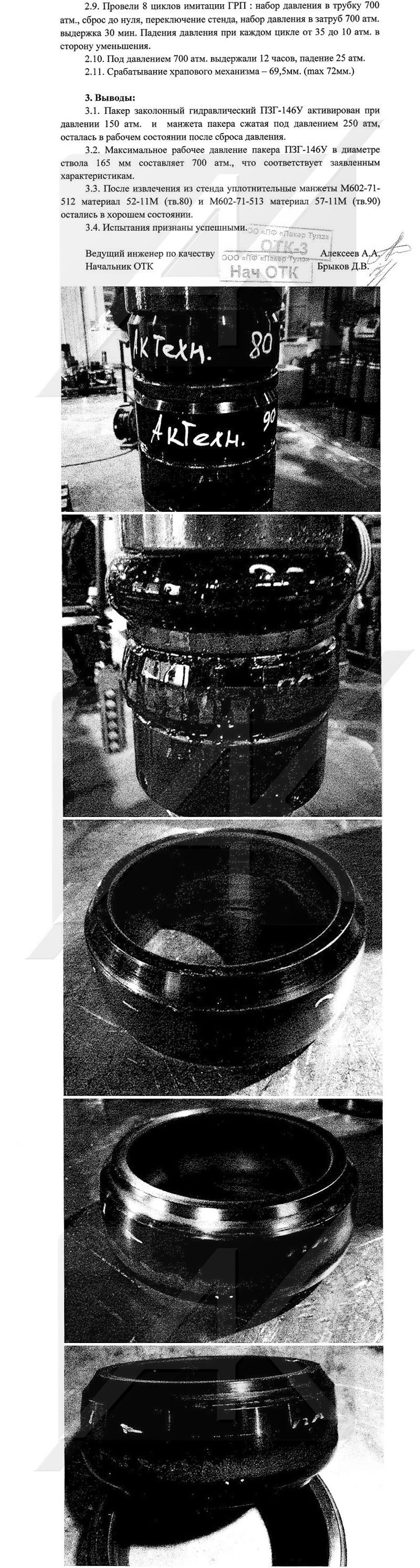

Test report of the sealing cuff of the packer, made by AvtokomTehnolodgy group of companies.

In addition to the development of the oil and gas sector, we are also expanding the range of food rubber products for enterprises that use bottling lines and conveyor equipment in contact with food products in their production.

Our company is ready to develop and produce for you any sealing elements with the required characteristics of strength and hardness. For the development of parts we need a technical task, both for rubber and for the manufacture of equipment.

In the technological process of manufacturing rubber products in our company, the following equipment is used: rollers, extruders, hydraulic presses, laboratory equipment for testing and determining the properties of rubber compounds.

For the manufacture of rubber used molds of its own production, developed by engineers of the design department and manufactured on CNC turning and milling machines with high precision positioning and machining parts.

en

en

Русский [ru]

Русский [ru]