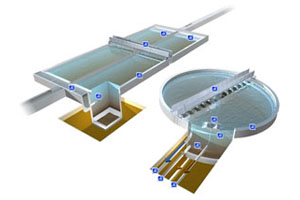

Sewage treatment plant is a set of measures and structures designed to purify the waste water prior to its recycling.

In these plants, municipal and industrial sewage is pumped to the treatment lagoons. Next, the crude precipitate as sludge from septic tanks in distilled methane-tanks where it is distilled and rotated by the pump through the heat exchanger. Eye-catching at the same time gas goes to electricity and heat generation. For these purposes, are now increasingly using sewage sludge.

The treatment plant pumps, commonly used single mechanical seals , running without washing (with conical seal chamber), or with circulation and flushing ( sealing with a cylindrical camera). Depending on the conditions of use, have proven themselves the following seals: NM-1, NMM-1.

Well proven mechanical seals for raw sludge pumps (KSB, KRK 150-37), are used in wastewater treatment plants operating in the mode without washing and tandem double mechanical seals used in the pump of sewage multiblock (Herborner, type Unipump) for pumping polluted liquids with a particle size up to 80 mm, in which the oil is the working fluid.

Sewage pumps (KSB, KWP) with mechanical seals NMM-1 of bio used in multistage units for biochemical nitrogen removal from refinery waste water with a high content of ammonium.

Seal life NMM-1, operating in a mode without washing (for example, 30 pumps nearly) is 3-4 years.

Submersible aerators for water saturation of oxygen in the lagoons, usually sealed mechanical seals NMM-1, NM-1.

Also, our seals are successfully operated in sewage pumps (Schulte type VP), in the special waste incineration plants and pumps with cartridge seal , pumping liquid products to rot or burn treatment.

Submersible pumps (ABS), permanently installed in the spillway or lagoons, sewage systems are equipped with tandem seals NM-1. For seal the submersible motor agitator (ABS, RW10-40 S), which serves to accelerate the flow of water and mixing in aerotanks treatment plants have successfully used mechanical seals NM-1 with a pair of friction SiC/SiC materials.

Paper stock pump (Ritz, series 38) for pumping domestic and industrial waste water containing solids, and sludge, sealed single seal NM-1, without washing. Submersible pump (HOMA, type A), permanently installed, for pumping waste water, faeces and slurry seal is equipped with a tandem NM-1.

Submersible pumps, because of their mobility, are widely used in construction. Waterproof and sealed design allows them to sewage treatment plants, as well as in stationary conditions.

Pump flow up to 5 000 000 liters per hour and lifting height is 70 m. Pumped medium is most often highly contaminated water with sand and stones from the construction pits. The concentration of particulate matter up to 50%, and the diameter of 30 mm, come across as rags, paper, etc.

Tandem seal series NM-1 bellows of elastomer reliably provide the shaft seal of submersible motor pumps, fans, mixers, etc. Materials pair of primary seal friction predominantly silicon carbide / silicon carbide. Flushing oil prevents dry running.

Also mechanical seals NM-1 equipped mobile submersible pumps ORPU Soffel and Jung UAK, for pumping clean and polluted water containing solids up to 5 mm.

Recommended types of seals for a treatment facilities:

| Device type | Materials | Seal type |

| Eccentric screw pump | Q1Q1VGG Q1Q1VGG/Q1Q1VGG |

Rubber bellows single seal Rubber bellows double seal |

| Centrifugal pump-sand catcher | Q1Q1VGG | Rubber bellows single seal |

| Waste water elevator | Q1Q1VGG | Rubber bellows single seal |

| Tube well pump | Q1Q1VGG/Q1Q1VGG | Rubber bellows tandem seal |

| Propeller pump | Q1Q1VGG/Q1Q1VGG | Double cartridge seal |

| Submersible motor agitator | Q1Q1VGG/Q1Q1VGG | Double cartridge seal |

Recommended types of seals for a thermal power plants:

| Type of pump | Materials | Seal type |

| Hot water circulation pump | AQ1EGG | Single seal |

| Feed water booster pump | AQ1EGG | Single seal with seat cooling |

| Feed water pump | AQ1EGG | Single cartridge seal with API Plan 23 |

| Main feed water pump | AQ1EGG | Single cartridge seal with API Plan 23 |

| Boiler circulation pump | AQ1EGG | Single cartridge seal with API Plan 23 |

| Condensate pump | AQ1EGG | Single cartridge seal with API Plan 11 |

en

en

Русский [ru]

Русский [ru]