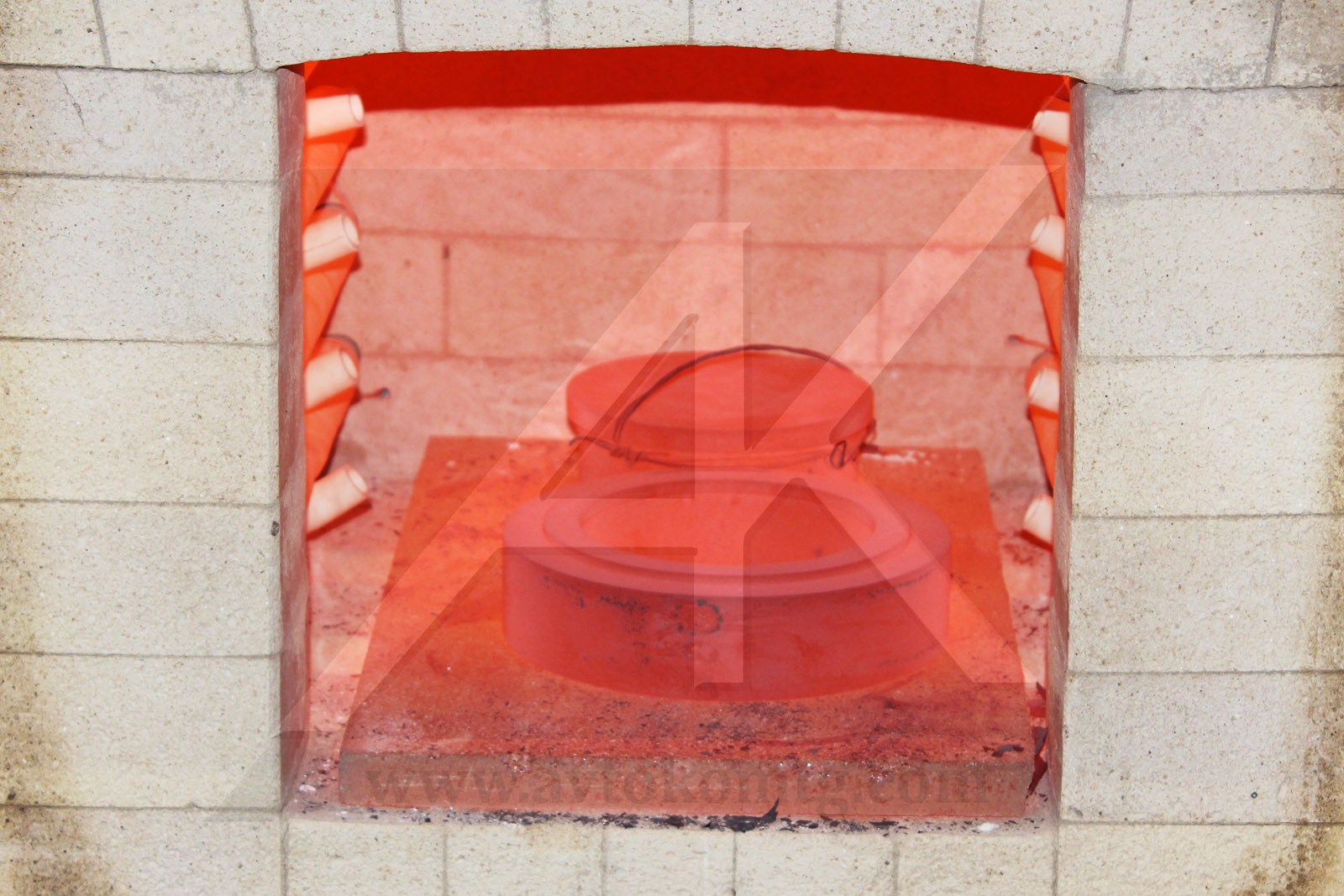

The AvtokomTehnolodgy group of companies carries out work on hardening billets or customer parts in volumetric hardening electric furnaces with a working chamber size of 500x300x290, LxWxH mm.

Heat treatment is the process of changing the structure of steel, non-ferrous metals, alloys during heating and subsequent cooling at a certain speed, leading to significant changes in their properties, in which the chemical composition of the metal does not change.

The heat treatment of steel and alloys can be of the following types: annealing, normalization, hardening, tempering.

Annealing is the heat treatment of metal, in which the metal is heated and then slowly cooled. This heat treatment can be of various types; the type of annealing depends on the heating temperature and the metal cooling rate.

Normalization is heat treatment is similar to annealing, their difference is that during normalization, the steel is cooled in air, and during annealing in the furnace.

Quenching is heat treatment of steel and alloys, based on the recrystallization of the metal when heated to a temperature above critical, after sufficient exposure at a critical temperature to complete the heat treatment, rapid cooling follows. Hardened steel or alloy has a nonequilibrium structure, so another type of heat treatment is applicable to them - tempering.

There are various types of hardening:

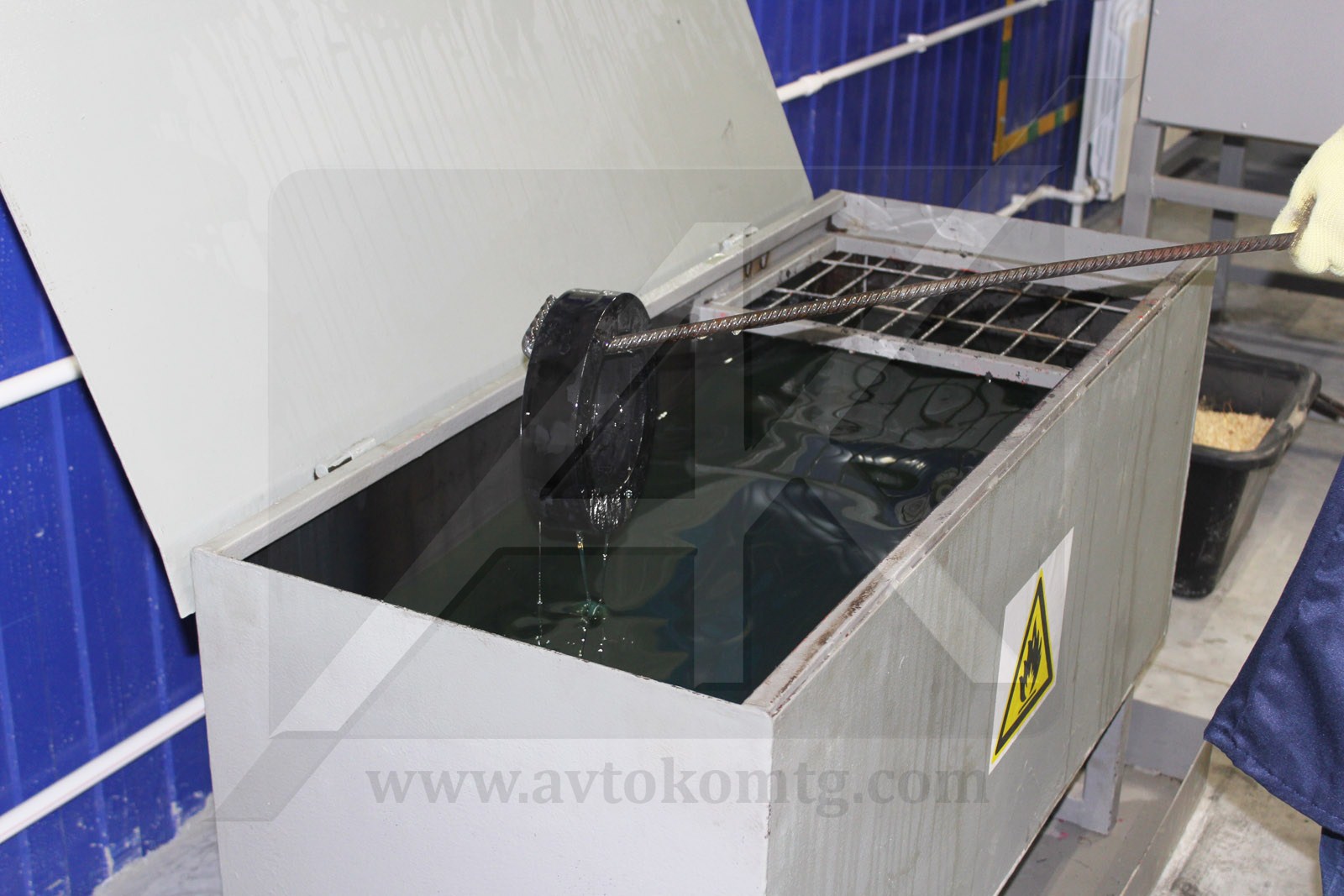

Simple hardening it is carried out in one cooler by immersing the part until it is completely cooled; for such hardening, water or an aqueous solution is most often used. When cooling, it is necessary to free the part from the vapor layer - this is the most common quenching method. To obtain high hardness, the greatest depth of the hardened layer for carbon steel, cooling of parts with intensive spraying is used.

Intermittent hardening is a cooling process sequentially in two environments: the first environment is a cooling liquid, in the role of which water is usually used; the second is air or oil. The sharpness of this hardening is less than the previous one.

Step hardening is a cooling process in which a part is quickly immersed in a molten salt and cooled to a temperature slightly above room temperature, where it is held for a short time and then cooled in air. Exposure provides equalization of temperature from the surface to the core of the part, which reduces stresses that occur during martensitic transformation. In our production, we use oil as a cooler.

Tempering is a heat treatment of steel and alloys carried out after quenching to reduce or relieve residual stresses in steel and alloys, increasing viscosity, reducing hardness and brittleness of the metal.

Hardening of metal molds significantly improves their hardness and wear resistance, which allows to increase the service life of PF and the number of work cycles, saving on the manufacture of additional PF in the production of a large batch of rubber goods, thereby reducing prices for the end customer for products manufactured by such a mold.

en

en

Русский [ru]

Русский [ru]